1- Thông tin chung :

- Phương pháp đo nhiệt độ của

bê tông trong cọc (The Thermal Profiling Method ) đầu tiên được phát triển tại

Trường Đại học Nam Florida. Sau đó hãng Foundation and Geotechnical Engineering

LLC (FGE) phát triển tiếp. Hãng PDI kết hợp với hãng FGE tiếp tục nghiên cứu và phát triển để hoàn

thiện công nghệ. Hiện nay, máy TIP được hãng PDI sản xuất và cung cấp trên toàn

thế giới và đã được đưa vào tiêu chuẩn ASTM D7949 -

Standard Test Methods for Thermal Integrity Profiling of Concrete Deep

Foundations.

- Nhiệt được sinh ra trong

quá trình đong kết xi măng. Bằng cách đo nhiệt độ của bê tông bên trong cọc,

máy PIT có thể đánh giá chất lượng cọc bê tông bên trong và bên ngoài lồng cốt

thép

- Việc đánh giá cọc có thể

được thực hiện từ giai đoạn đầu của quá trình đông kết ( sớm hơn 12h)

- Máy TIP cũng được dùng để

đánh giá chất lượng và biên dạng của

tường vây

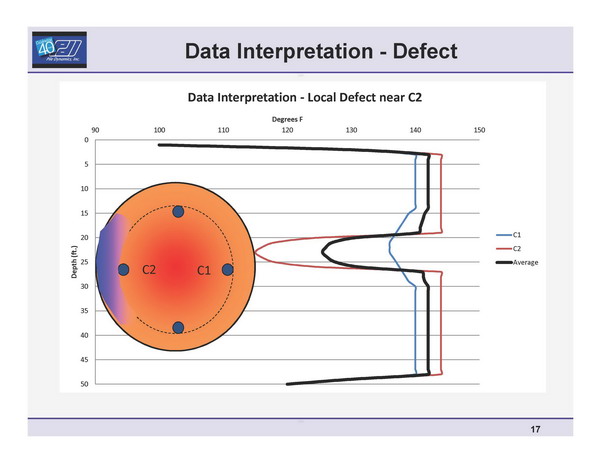

- Kết quả thu được trong thời

gian ngắn kể từ khi đổ xong cọc, bao gồm : chỗ bị co thắt ( vùng mà nhiệt độ

thấp hơn so với trung bình), chỗ phình ra (vùng mà nhiệt độ cao hơn nhiệt độ trung

bình), sự thay đổi trong lớp bê tông và hình dạng của cọc và sự thẳng hàng của lồng

cốt thép.

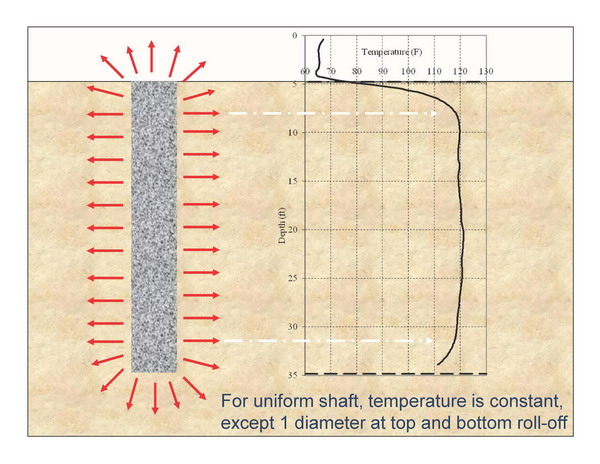

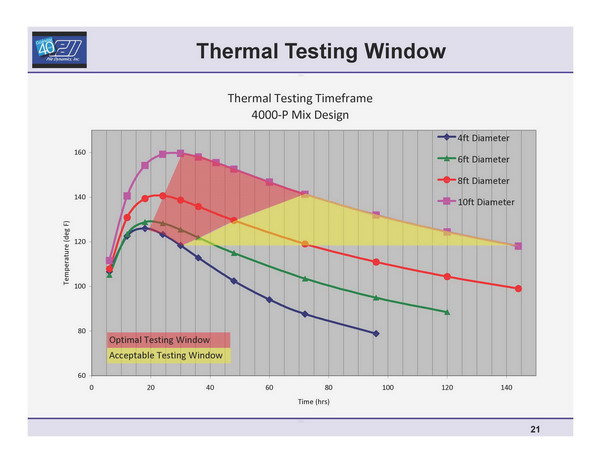

- Nhiệt độ trung bình của bê

tông trong cọc phụ thuộc vào đường kính của cọc, thiết kế hỗn hợp bê tông

và thời gian của phép đo trong quá trình

đổ. Nhiệt độ đo được tại các điểm trên

lồng cốt thép thay đổi phục thuộc vào

khoảng cách của điểm đo đến đường tâm của cọc và lớp vỏ bê tông.

- Các ưu điểm của máy TIP :

+ Đánh giá chất lượng bê tông

theo toàn bộ mặt cắt hay toàn bộ chiều dài cọc

+ Không bị ảnh hưởng bởi tách

lớp

+ Không cần lắp đặt ống siêu

âm ( khi dùng phương pháp đo bằng dây)

+ Đẩy nhanh quá trình thi

công ( 24 đến 48h kể từ khi đổ xong cọc đã có kết quả trong đối với phương pháp

siêi ẩm phải đợi 5 đến 7 mới có thể đánh giá được chất lượng cọc)

+ Giảm đáng kể giá thành

- Máy TIP được cung cấp với 2 cấu hình : Dùng dây cáp có sẵn các sensor hoặc dùng đầu dò

để đo nhiệt độ

+ Máy TIP- loại dây bao gồm các

dây cáp có gắn sẵn các đầu đo nhiệt độ ( các đồng đo được thiết kế với khoảng

cách nhất định và bằng nhau), bộ thu thập số liệu ( để lấy tín hiệu từ các đầu

đo và truyền đến máy chính) và máy chính. Các dây cáp được chôn cùng với cọc bê

tông (thông thường được buộc vào lồng cốt thép). Để có thêm số liệu đánh giá

chất lượng bê tông, người ta cũng thường làm thêm 1 đoạn cáp ngắn khác buộc song song với 1 trong các cáp chính

+ Máy TIP-loại dùng đầu dò

bao gồm 1 đầu do nhiệt độ ( có 4 sensor đặt trực giao theo kiểu chữ thập), bộ thu thập số liệu ( để lấy tín hiệu từ các

đầu dò và truyền đến máy chính) và máy chính. Đầu dò được thả vào ống siêu âm (sau khi hút hết nước) để

đo nhiệt độ bên trong. Với loại này, cọc nhất định phải được bố trí sẵn các ống

siêu âm.

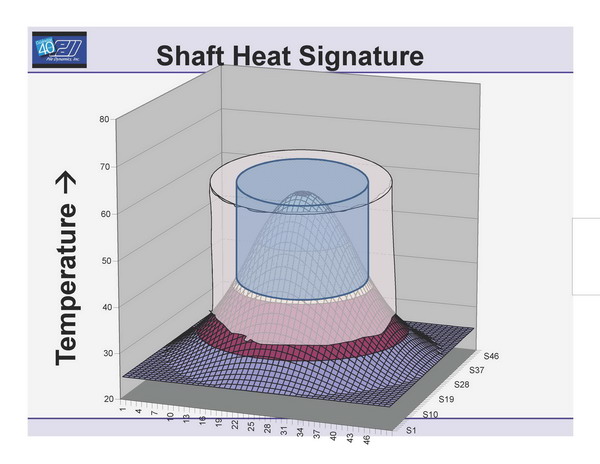

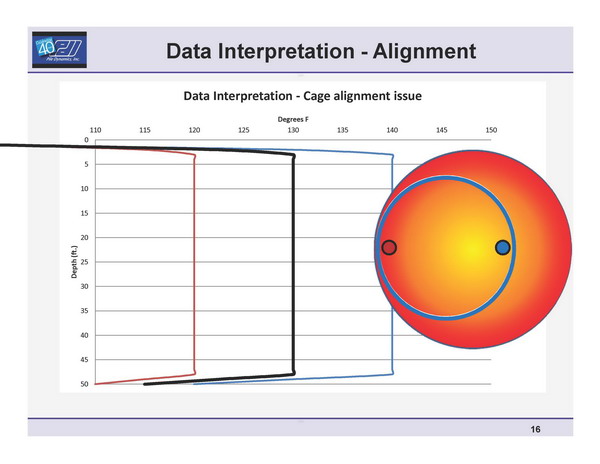

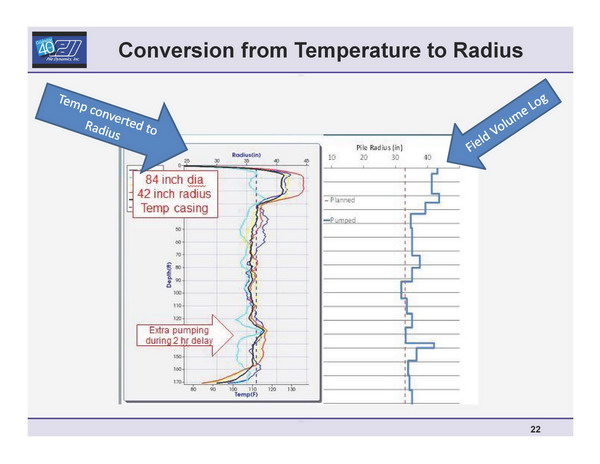

- Các số liệu thu thập được

từ máy TIP sẽ được truyền đến máy tính. Sau đó 1 phần mềm chuyên dụng sẽ cho

phép người sử dụng phân tích số liệu cũng như làm báo cáo. Đồ thị báo cáo sẽ

hiển thị nhiệt độ đo được theo chiều sâu của cọc cũng như nhiệt độ cho từng mặt

cắt của cọc. Với các đồ thị thu được,

chúng ta có thể đánh giá cọc có đồng

nhất nguyên vẹn hay có bị khuyết tật hay không

2- Các thông số kỹ thuật của máy TIP :

Máy chính :

Kích thước: 135 x 104 x 52 mm

Khối lượng: 0.45 Kg

Màn hình VGA mầu cảm ứng ,

hiển thị trong mọi điều kiện ánh sáng, độ phân dải cao 640 x 480 pixels

Kích thước màn hình: 9.4

cm

Hoạt động bằng pin Li-Ion

Bộ vi xử lý điện tử : PXA270

@ 520 MHz

Bộ nhớ trong : 1 GB , có cài

sẵn cổng USB để thu nhận và truyền số liệu

Bộ thu thập số liệu cho loại đầu dò nhiệt độ (TAPP) :

Kích thước: 114 x 133 x 57 mm

Khối lượng: 822 g

Hoạt động bằng pin Li-Ion

Thời gian hoạt động : 8 giờ

Tần suất lấy mẫu : 1 mẫu/giây

hoặc theo chiều sâu (người sử dụng tự đặt)

Nhiệt độ làm việc: 0 to 40°

C; lưu giữ 20 to 65° C

Đầu dò nhiệt độ :

Loại đầu dò: dùng hồng ngoại (4

đầu đo đặt trực giao kiểu chũe thập)

Kích thước: 127 x 30 mm

Khối lượng: 5.2 kg

Chiều dài cáp: 60 m

Nhiệt độ làm việc: đến 105°C

Bộ đo chiều sâu :

Loại: bộ mã hóa quay (giống

như đầu đo chiều sâu của máy siêu âm)

Độ phân giải: 2.5 mm

Bộ thu thập số liệu cho loại dây (TAP) :

Kích thước: 133 x 102 x 57 mm

Khối lượng: 766 g

Nhiệt độ làm việc: -20 to 65°

; lưu giữ : -40 to 85°C

Hoạt động bằng pin Li-Ion

Thời gian hoạt động : 30 ngày

Tần suất lấy mẫu : người sử

dụng tự đặt hoặc lấy theo mặc định ( 1 mẫu cho mỗi 15 phút)

Dây có thể được buộc vào lồng

cốt thép và cũng có thể được bắt bằng bu lông cho an toàn

Dây cáp có các sensor nhiệt độ :

Loại: số

Cung cấp theo cuộn, tối thiểu

là 6m (20 ft). Chiều dài hơn có thể chọn

tùy ý nhưng phải là bội của 1.5 m (5 ft)

Khoảng cách giữa các sensor:

305 mm

Nhiệt độ làm việc: đến 105°C

Các thống số khác :

Model PITđáp ứng tiêu chuẩn ASTM D7949

Đơn vị đo: hệ Anh hoặc SI

Phần mềm cơ bản TIP

Sách hướng dẫn sử dụng

Bảo hành 1 năm

3- Các ví dụ kết qua thu được từ máy TIP :